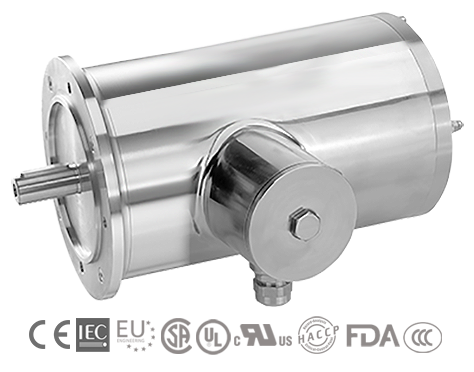

STARK Stainless Steel

Foodsafe quality drives

STARK Stainless Steel Motors

We know that in addition to maximum production and profit, your highest priority is product safety.

Legal requirements in the field of food safety are becoming increasingly strict, both at European level and worldwide.

To guarantee this safety STARK electric motors produces efficient, hygienic, economical and sustainable stainless steel motors

with a high return on productivity, efficiency and usability.

Advantages and features of STARK stainless steel motors:

- Available in IE3 and IE4

- Food-grade quality

- IP69K protection class

- Anti-condensation heater

- Smooth surface for easy cleansing

- Equipped with VITON O-rings/seals

- Special one-way membrane pressure valve

- EU-engineered components

- Molded terminal block

- Two-year warranty

Contact us and learn more

Applications of stainless steel electric motors

STARK stainless steel motors are the ideal solution for environments where the highest hygiene standards apply, but also in situations where extremely high humidity and frequent cleaning cycles occur. Companies around the world use STARK stainless steel electric motors in various industries, applications and machines:

Would you like to know more about STARK stainless steel motors?

Case study

Efficient drive for hygienic poultry processing

A machine builder of fully automatic poultry processing lines was looking for a stainless steel motor that would fit perfectly in their fully automatic poultry processing line and that combined durability, hygiene and reliability while optimizing the efficiency of the cutting process.

This machine builder found the ideal solution in STARK’s stainless steel motor. STARK supplied V19 stainless steel electric motors with an IP69K rating, especially for driving cutting blades in poultry processing lines. The engines are equipped with advanced drainage channels to efficiently remove waste and water and protect vital seals. With the implementation of STARK engines, the customer offers a reliable, sustainable and hygienic processing line in accordance with the highest safety standards and the requirements of the poultry processing industry.

“STARK’s stainless steel motors not only provide the power and efficiency we need for our poultry processing lines, but also meet the highest hygiene standards. The motor is a crucial part of our systems and contributes to ensuring food safety in production processes.”

STARK stainless steel: high-quality motors at competitive pricing

STARK stainless steel electric motors are the answer to the demand for reliable high-performance stainless steel motors that meet European standards and at the same time are available at a very favorable price at an extensive network of European distributors.

Fast delivery

Safe packaging

International distribution